Delta

ILAPAK’s flow pack & flow wrappers can be tailored to match each customer’s specific needs, and deliver maximum production flexibility and efficiency at each performance level. Every model is available in different configurations with a large range of options to choose from.

Description

Delta 500

ILAPAK's entry level horizontal flow wrapper (HFFS) for modified atmosphere (MAP) applications, with ILAPAK 's leading Long-Dwell (LD) sealing technology. The Delta 500 is the ideal machine for packing irregular shaped products, featuring a variable cut off length according to product length. The standard configuration of the Delta 500 includes bottom film feeding (inverse machine) and is controlled by an industrial PC. One of the most effective ways to extend the shelf life of fresh products is to pack them in a hermetically sealed pack with a modified atmosphere.

Our robust Delta flow wrappers are precisely engineered to ensure hermetic sealing at high speed. Thanks to the flexibility of its design, the Delta series of machines are also ideally suited for non-food applications where a hermetically sealed pack is required, such as medical and personal care products like wet wipes.

Delta 3000

ILAPAK's Delta 3000 is PC controlled and equipped with long dwell technology for modified atmosphere (MAP) to cover the widest range of applications and includes ILAPAK's unique high speed hermetic sealing technologies. It’s heavy duty and reliable design allows the Delta 3000 to be integrated in automatic packaging systems. Machines are also available in stainless steel and bottom film feeding versions. The Delta 3000 LDR allows for the handling of delicate and irregular sized products.

One of the most effective ways to extend the shelf life of fresh products is to pack them in a hermetically sealed pack with a modified atmosphere. Our robust Delta flow wrappers are precisely engineered to ensure hermetic sealing at high speed. Thanks to the flexibility of its design, the Delta series of machines are also ideally suited for non-food applications where a hermetically sealed pack is required, such as medical and personal care products like wet wipes.

Delta 6000

The new Delta 6000 is a new fully modular design flow wrapper that offers complete IP65 protection, enabling full wash down capability, even of the sealing elements. The Delta 6000 flow wrapper incorporates a new higher speed long-dwell sealing system for MAP applications up to 200ppm such as meat, cheese, pizza and bakery products

Delta 6000 3 Side Seal

New open frame flow wrapper with long dwell technology to cover the widest range of pack styles including high speed zipper with MAP. Its specific mechanical design, driven by servo motors and PC control platform makes it not only easy, fast and reliable in size change operations but also when automatically changing to different packaging style i.e. from standard pillow pack to the three (3) side seal pack style. The Delta 6000 3SSC includes the latest hygienic design requirements, stainless steel construction and a wide range of re-closable packaging solutions.

One of the most effective ways to extend the shelf life of fresh products is to pack them in a hermetically sealed pack with a modified atmosphere. Our robust Delta flow wrappers are precisely engineered to ensure hermetic sealing at high speed.

Delta Flobag

ILAPAK’s dedicated solution for replacing shrink bags, it’s the most efficient solution to shrink and vacuum processed meat and cheese. This ILAPAK solution can range from a stand-alone HFFS flow wrapper with long dwell technology or a complete solution to meet different market needs. All Flobag flow wrappers are electronically controlled and equipped with variable cut off length control to minimize and optimize film usage. The stainless steel and hygienic design allows the machine to work in harsh and wash down environment.

Strong hermetic seals, complete flexibility and rugged, ultra-hygienic full stainless steel construction characterise the all new Delta Flobag BM, a system designed to allow customers to replace their more expensive pre-made bag solutions with lower cost film from a reel. The exceptionally strong seals created by the full box motion sealing head can easily withstand a vacuum cycle, making this new HFFS solution ideal for many larger sized fresh meat and cheese products. Available as a top or bottom reel machine, the Delta Flobag BM is particularly suited to lines running a variety of products, such as larger foodservice blocks of cheese, different sized cuts of primal fresh meat and processed meat, as the machine automatically cuts the pack size to each product’s dimensions.

One of the most effective ways to extend the shelf life of fresh products is to pack them in a hermetically sealed pack with a modified atmosphere. Our robust Delta flow wrappers are precisely engineered to ensure hermetic sealing at high speed.

Delta 6000 BM

Strong hermetic seals, complete flexibility and rugged, ultrahygienic full stainless steel construction characterise the all new Delta 6000 BM, a system designed to allow customers to replace their more expensive pre-made bag solutions with lower cost film from a reel. The exceptionally strong seals created by the full box motion sealing head can easily withstand a vacuum cycle, making this new HFFS solution ideal for many larger sized fresh meat and cheese products. Available as a top or bottom reel machine, the Delta 60000 BM is particularly suited to lines running a variety of products, such as larger food service blocks of cheese, different sized cuts of primal fresh meat and processed meat, as the machine automatically cuts the pack size to each product’s dimensions.

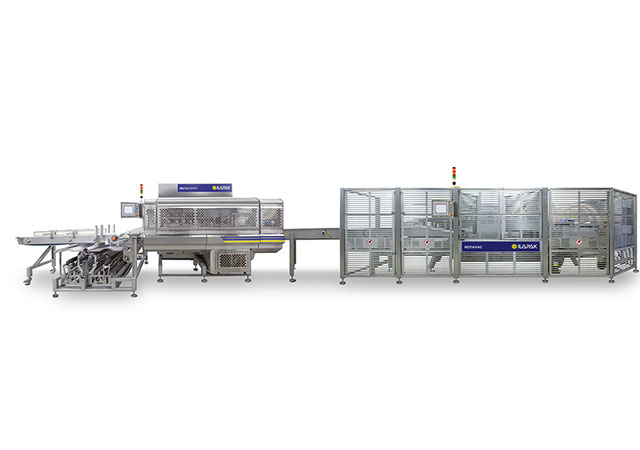

Delta RotaVac

The new Delta RotaVac® system seamlessly integrates Ilapak’s Delta 6000 flow-wrapper with an innovative rotary vacuum chamber that is optimised for applications whether fresh primal meat cuts, retail, food service or cheese products. This has created a highly efficient and labour saving solution for replacing more expensive pre-made shrink bags with lower cost film from a reel. Reduce labour by 60% versus pre-made bag solutions, thanks to the labour reducing, fully integrated solution Ilapak Delta RotaVac®.

Delta VacMap

A unique ILAPAK flow wrapping concept is the Delta VACMAP™, the modified atmosphere system with long dwell wrapper technology provides a versatile and automatic solution for different MAP applications allowing gas flushing & vacuuming at the same time when producing the different packaging styles pillow pack or shrink packaging. Implemented over one automatic system, this machine is ideal for bakery and pizza packaging.

Lux 24

Lux 24, High speed pouch machine for Pillow and Doypack solutions.

The Ilapak Lux 24 is a revolutionary new range of innovative high speed pouch machinery with an unique dual motion system composed of an intermittent station for pouch forming and sealing and a continuous station for product filling.

This brand new Ilapak solution has been designed to form flat film roll stock into high quality Doypack bags with fully integrated filling solutions for liquids, solid, powder or granules products.

Given its versatility, Lux 24 is suitable for a wide number of applications including detergent liquid/powders, sauces, soup, beverage, candies, cereals and grated cheese. The Doy pouches packaged by Lux 24 can be equipped with spout, straw or zipper and even fitted with handle.